ELENICA : The First supercar featuring a Parametric Chassis.

Newspaper Article (Translated) : 2016, February 16 :

Parametric Chassis and Suspension

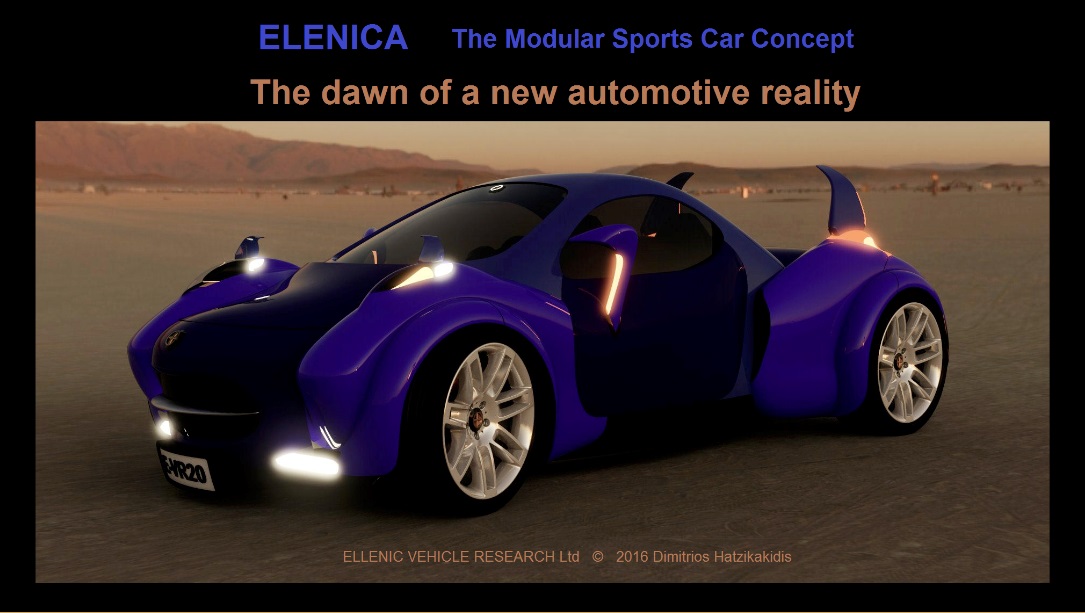

Module Technology : The vision of Dr. Dimitrios Hatzikakidis and his

associates, who aspire to change things in the auto industry, takes shape through

the first high-end application, which has been introduced as the “Modular

sports car concept”.

This first application of their

innovative design model for cars, applicable to various categories, presented

by Hatzikakidis and his team, has had repercussions in Europe, America and

Asia.

The high-end sports car application

: “Elenica”, is the “flagship” of the on-going projects, puts on the map all

the advantages of the technology and the resulting new design methods. This

opens the way for the ground-breaking, game-changing changes in the manufacture

of electric/hybrid vehicles, conventional low-cost cars, high performance

sports cars (expensive prototypes) and military vehicles, all utilizing the

“parametric chassis recipe”.

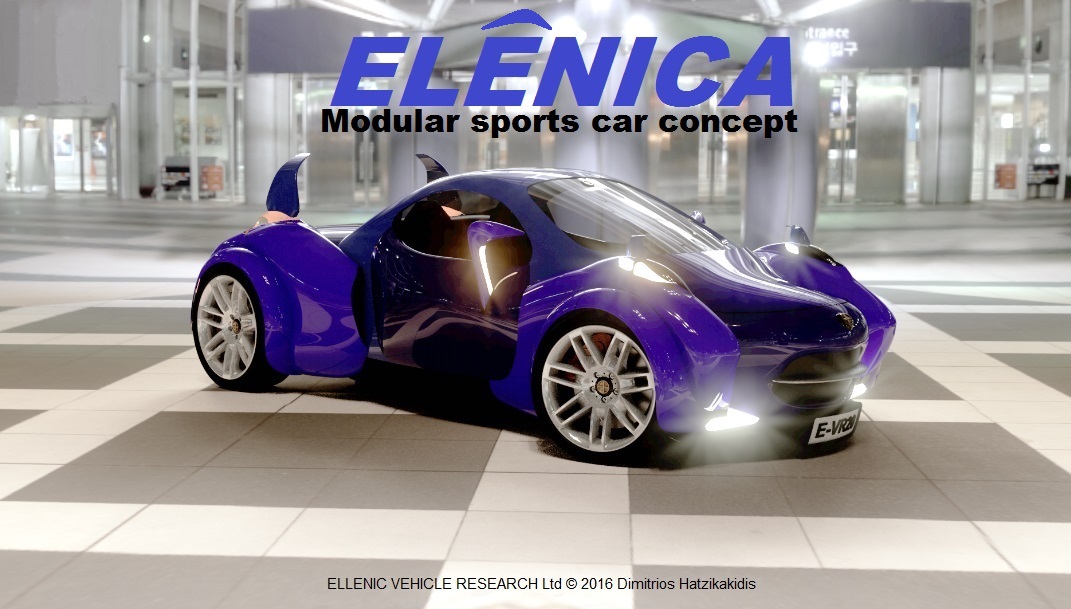

"Elenica" is now being developed in

Switzerland and in England and it will be ready for presentation in a few

months. It is equipped with a series of original features that appear for the

first time in the world car industry and are based on the parametric chassis/suspension

module and other innovative technologies” says Hatzikakidis. Elenica

incorporates patented aerodynamic technology, the new flashing/trafficator

light cluster on the rear-view mirror, (an evolution of the original, designed

by Hatzikakidis, 30 years ago at Mercedes) and other innovative design

solutions. “Our plan is based on a technological and financial analysis that

fully covers the spectrum of design/development/manufacturing for

electric/hybrid, conventional, sports and military vehicles” he adds.

R&D Jobs

Apart from the (apparent)

technological advantages, the new design method addresses many of the

challenges the world car industry is faced with and can cope in the years to

come, as it creates a new market, (that of the “suspension module and the

parametric chassis”). This contribution could play a pivotal role in research

and development (R&D), creating jobs for engineers and scientists, as the

technology may “unlock” thousands of posts in a Europe faced with depression

and high unemployment.

The parametric chassis technology

promises wealth creation for countries involved in the process of car

design/development/manufacturing, slashing the manufacturing cost and helping

companies overcome a series of red tape and technical-financial impediments. It

is no coincidence that the major car industry players (multinationals, OEMs,

design-houses, international research and industrial applications agencies) are

following every step of Hatzikakidis and his team, who have managed recently to

secure new patents and develop new prototypes, despite the … trip ups attempted

by certain OEMs (attempting to copy patents and design solutions), in order to

reap some benefits from the development of this new technology.

Influential figures in the industry

admit however, that attempts of this kind are “at-the-end-of-the-day

counter-productive”, since one of the major advantages of the “parametric chassis

and the suspension module technology” is that it has the ability to evolve

continually into many directions, creating new technological sectors and

markets. It seems unavoidable, therefore, that the big companies will

eventually cooperate with the Hatzikakidis team, to the benefit of the global

car market, which swirls in the spin of economic crisis and stagnating

technology.

"We can keep creating new

applications and dozens of new patent-trees on the technology we have created.

It would, therefore, be to the OEMs’ advantage to cooperate with us, instead of

striving to benefit from our technology, without us. Further, we have in our

hands a technology that allows us to simplify the production process by keeping

certain sections of high precision and low tolerance, manufactured in Europe

and completing final assembly overseas, where the manufacturing cost is lower.

For instance, the suspension module could be made in Europe and be sent for

final assembly to Asia or Africa. Keeping the industrial production in Europe

is something the European politicians and industrialists were unable to

implement in the recent decades, as part manufacturing in Asian countries was

the only choice, given that all existing traditional technologies have “reached

total depreciation” and the only criterion is “a low industrial cost”. With new

technologies, of the type we are creating, the end benefits of 1 less weight, 2

better performance and 3 cost-effective upgradeability potential are

accomplished “by design”, thanks to the new, innovative, original design of the

product and the procedures developed” explains Dr Hatzikakidis.

Suspension modules and chassis give

a car game-changing advantages.

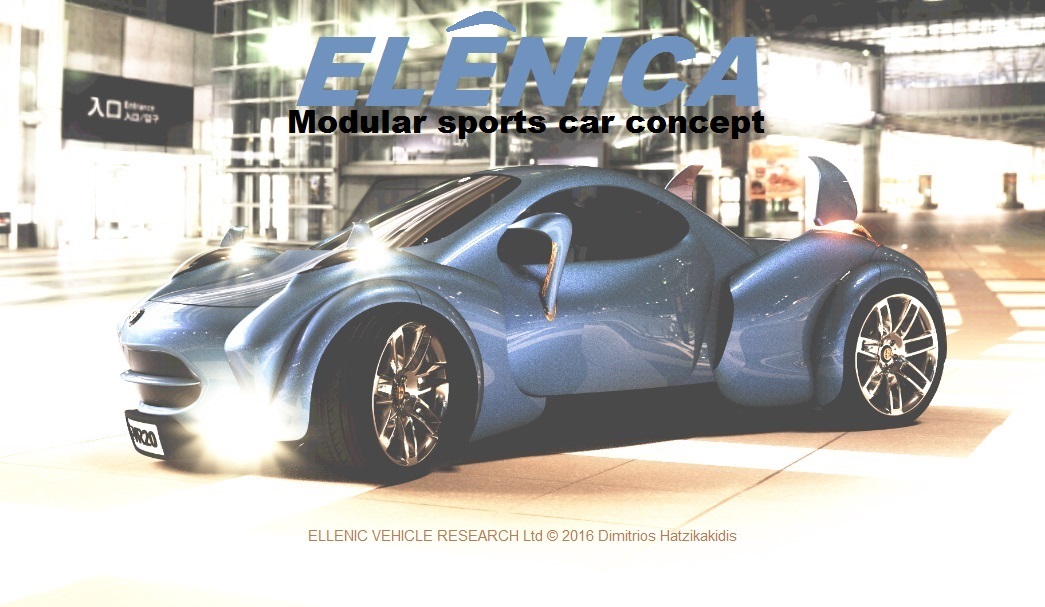

The parametric chassis and the

suspension module technology, that focuses on the original design and frees the

external styling, is based on an initial simple array of suspension and chassis

that offers a vehicle flexibility, comfort and quality characteristics of much

more expensive cars. Instead of the four conventional suspensions in use today,

we fit four times, at the chassis corners, the same (fully adjustable)

suspension module, thus, creating the parametric chassis. In the case of

electric/hybrid vehicles the suspension module is also equipped with an

electric motor, while the usually heavy and bulky batteries are accommodated at

centre of the chassis. In this way we make an original chassis that endows the

car with improved structural rigidity, crash characteristics and reduces its

overall weight impressively.

“The chassis may be built much

lighter, with optimal separation of subsystems (e.g. control collapse zones).

The parametric chassis technology introduces us also to the innovation of the “complementary self carrying body”, as it has been

patented by us, in Japan in 2015, which allows the building of a car 250 kg

lighter” explains Dimitrios Hatzikakidis.

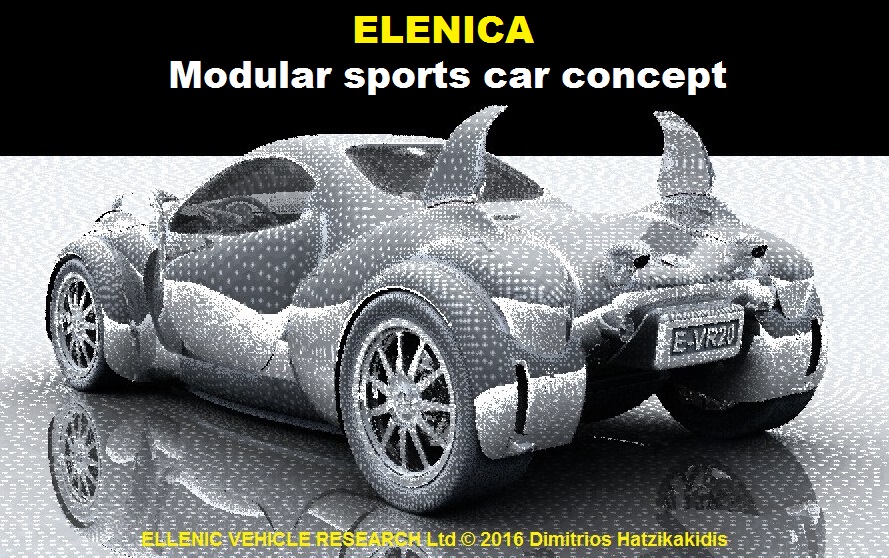

Seven road-going prototypes are now

being developed and tested :

The suspension module is adjustable

with upgradeability options into three levels : “Functions at the visco-elastic

level, is upgraded to an electromechanical system and reaches an

electromagnetic suspension/harvesting array, at (comparatively) lower cost. The

upgrading extends also to the active / adaptive level. We have categorized more

than 50 parameters for design, evolution and industrialization, that have been

thoroughly studied in the recent years” Hatzikakidis points out.

His team, with associates in

various countries, can fully cover mechanical and technological issues, to

handle matters of copyright and business strategy and satisfy the trends of

contemporary marketing. “We have worked out extensive business plans at four

levels of application: a) intellectual property, b) limited industrial

application, with manufacture of sections of our suspension modules, c)

industrial application of the entire parametric chassis, d) manufacture of a

complete car with our technologies. There is a wide field of implementation

from conventional vehicles to electric, electric/hybrid and military vehicles.

In total seven vehicles are now at the stage of testing, among them two “Modular

Sports Car Concept” vehicles, that will lead us to the (super)car

Elenica”.

The Parametric Chassis and Suspension Module innovation

(Translated Newspaper Article : 2013, May 11)

Emphasis on innovation, can be used for the design of vehicles across the board, reduces the time and cost in Design / Development, manufacturing / assembly of

new models and is ready for future technologies.

The Suspension Module and the technology of the “Parametric Chassis”, created by

the mechanical-engineer, Dr Dimitrios Hatzikakidis, and his team, may change

things in car Design and Manufacturing. The starting point is an (initially) simple and

effective assembly, (the suspension module), that is used to make up a light and

robust chassis. It involves a number of worldwide patents, dozens of filings with the

international patent offices, in all the major markets.

"The most important aspect of the invention is the design of the “chassis and the

suspension as one unit”. The use of a “standardized suspension module”, placed at

the four corners of the frame, in addition to “wheelbase elements”, which are cut to

size in order to "build" the floor of the vehicle, decreases cost. “Vehicle

manufacturers usually avoid change, due to fear. But in this case there is no risk, the

financial payback is immediate ", says Professor Konstantinos Spentzas, founder of

the Road Vehicle Laboratory, School of Mechanical Engineering of NTUA, who

follows the evolution of this technology for over 15 years.

“The new design method based on the technology of the “Suspension Module and

the Parametric Chassis”, gives a vehicle more stability and offers features of a much

more expensive car. The use of a rotational-damper, instead of a linear

(reciprocating) damper, is another major innovation. The rotary application is more

energy efficient, and now allows the adoption of very expensive technologies, at a

lower cost. This new module can also be used in designing any traditional

conventional) suspension, (such as double wishbone or multi-link), giving us the

opportunity to reach out into new automotive applications, and various vehicle

production processes”, says Prof. Spentzas.

“Save energy and money by the application of a common (and fully adjustable)

Suspension Module is a double mission." Dr Hatzikakidis explains, "each suspension

module functions as both a “spring” and a “damper”. It is something that happens for

the first time ; as until now, the two elements were separate and connected in

parallel. For the last 90 years, this was done due to the respective historical origins,

of the two separate components (spring, damper). In our new suspension module

(and chassis), the energy accumulation /dissipation occurs at the same time, and in

the same place ".

The “Suspension Module and the Parametric Chassis technology” over the last 15

years, has prompted Dr Hatzikakidis and his colleagues to develop many novel

“implementation and innovation” strategies. This technology can be applied in

conventional, commercial, hybrid / electric vehicles, but also has a very important

military application, in vehicles and tanks. Moreover, it creates an entirely new

market in a “suspension module product”, that up until now, were just ‘spare parts’.

"The idea of the suspension module allows us to change both the

design/development process of vehicles, as well as, the manufacturing/assembly

processes. This prompted us to adopt completely innovative processes in strategies

and tactics in Product Design, Research & Development, Intellectual Property in all

the major markets worldwide. In the last few years, we had to apply innovative tactics

in Research (R & D, Industrialization) for our experimental technology, while

developing technology demonstrators and pre-industrial prototypes simultaneously in

many markets. Also, we are creating an entirely new market for suspension modules.

Our other big goal is connecting to Overall Vehicle Design and Styling, many of our

key technological advantages and innovations. One such example is the application

of our “Controlled Discontinuity” Design process, Hatzikakidis notes.

The technology of the suspension modules primarily focuses on chassis and car body design, which serves as the “basis” for creating the styling of a car. At a time

when traditional design - style companies fail because of the financial crisis, Dimitrios

Hatzikakidis presents a completely different model for vehicle design, bringing

innovation to the fore and provide a new proposal to produce products on a global

scale.

Can adapt to future applications

The biggest advantage of this model is its ability to "keep up" with technological

developments. "The Parametric Chassis “opens the door” to a new generation of

technologies and can be adapted to future applications in the coming years. Making

currently very expensive technologies (such as active / adaptive, variable springing /

damping) much cheaper. “Exotic” future applications can be made cost-effective

within our existing framework", says Dr. Hatzikakidis. It is worth noting that the new

innovative method in vehicle design/assembly has already attracted the interest of

two multi-nationals, several design firms, major OEMs and institutions in China and

Hong Kong.